A new £500k digital testbed, which will create a “step change” in smart manufacturing, is being built at Queen’s University to help develop new technologies and grow market opportunities for businesses.

A collaboration between Queen’s, BT and Cisco, the project is part of a co-investment to create a 5G enabled digital factory.

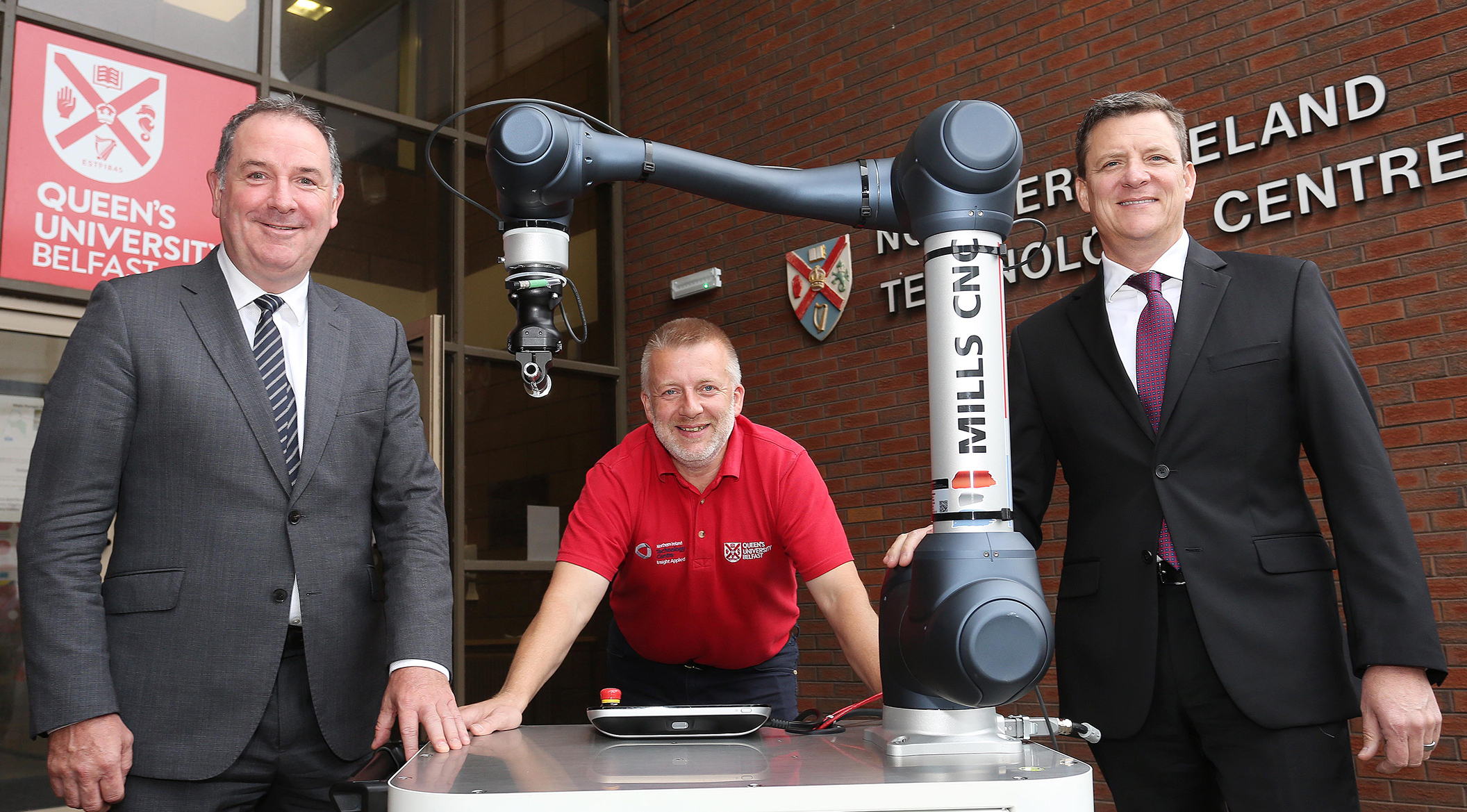

The testbed, which will be based at Queen’s University’s Northern Ireland Technology Centre (NITC), will provide a unique opportunity for local industry to collaborate and explore the benefits of 5G connectivity within their future manufacturing operations.

These new technologies will lead companies to pursue increased digitalisation of factories, adopting smart factory technologies including automation and robotics, allowing them to become more efficient, productive and less wasteful and to compete on the global stage.

The facility will also provide an invaluable resource for researchers at Queen’s to translate their research to industry in the areas of Digital Twin, Cyber Security, Digitised Manufacturing, Sensors and other Industry 4.0 activities.

The project will build on existing research in smart factory technology, which has been taking place through the University’s iAMS (intelligent autonomous manufacturing systems) Pioneering Research Programme and Project SCENIC, which is supported by Invest Northern Ireland’s Research & Development programme.

Head of the Northern Ireland Technology Centre, Colm Higgins, comments: “As the manufacturing sector moves towards digital technologies and supporting Industry 4.0, digital testing is vital in helping to improve performance and quality of production. 5G technology offers higher speeds, greater capacity and shorter response times to the digital environment.

“This £500k investment by BT, Cisco and Queen’s is an important collaboration of academia and business and will help us to deliver our mission of driving innovation and creating solutions from R&D. This will in turn help to grow market opportunities and create a step change in smart manufacturing.”

Paul Murnaghan, Regional Director for BT’s enterprise business in Northern Ireland, adds: “We are delighted to be investing in a new collaboration with Queen’s University’s Northern Ireland Technology Centre. As the third largest investor in R&D in the UK, BT is committed to leading the way in creating strategic partnerships like this that will help to benefit local businesses across Northern Ireland.

“By working together alongside local manufacturing businesses, we hope that the Industry 4.0 manufacturing testbed at the NITC will identify, test and prove real business benefits for the sector with the creation of new smart and automated technologies as we move into the Fourth Industrial Revolution.”

Shane Heraty, Managing Director, Ireland and Scotland, Cisco, says: “The smart manufacturing test centre at NITC will help organisations to trial leading-edge technology and processes that have the potential to position them at the forefront of Industry 4.0 in Northern Ireland.

“Industry 4.0 provides opportunity to modernize and leverage the benefits of digitization, optimizing production and utilising real time data to make smarter and faster decisions. We’re proud to be working with Queen’s and BT through our Country Digital Acceleration programme, which aims to help build a more digital and inclusive society.”